Pushback Rack Systems | High-Density Pushback Pallet Racking & Storage Solutions

Elevate your warehouse efficiency with our premium pushback rack systems, the ultimate solution for high-density storage. Designed for seamless material handling, our pushback pallet racking allows pallets to glide effortlessly on wheeled carts, enabling Last-In-First-Out (LIFO) access that doubles your storage capacity compared to selective racking. Whether you're managing heavy inventory or tight spaces, our push back racking system and push back pallet rack system deliver durability, safety, and scalability—perfect for industries like manufacturing, distribution, and logistics. Contact us today to transform your push back rack operations.

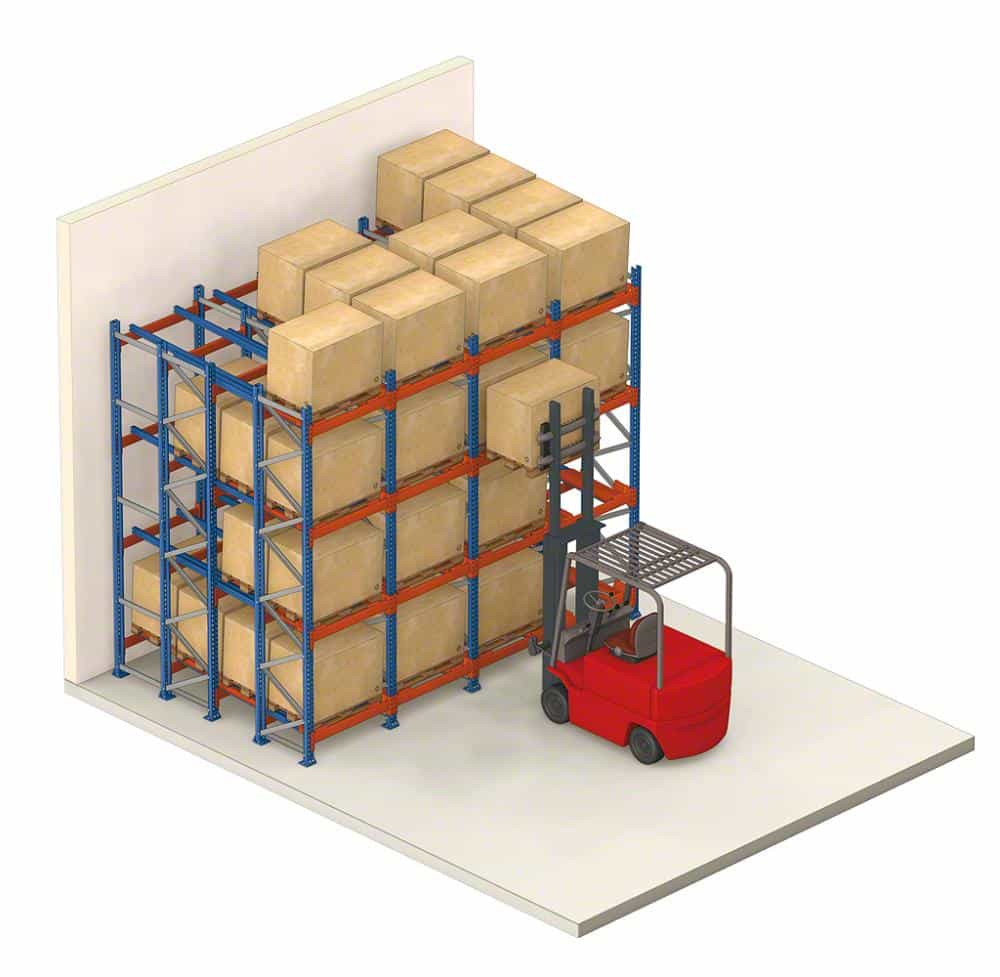

How Push Back Racking Systems Work

Our push back racking system operates on a simple yet ingenious principle: gravity-assisted wheeled carts

- Loading Process: Insert the first pallet onto a cart at the front bay. As you add subsequent pallets, each new one pushes the previous carts deeper into the rack lanes—up to 6-10 pallets deep per lane.

- Cart Design: Heavy-duty steel carts with nylon or steel wheels roll smoothly on inclined rails, ensuring even weight distribution and minimal friction.

- Retrieval Process: When unloading, remove the front pallet, and gravity pulls the next cart forward automatically. No manual pushing required, reducing labor and forklift time.

- Safety Features: Built-in stops, load dividers, and optional sensors prevent cart runaway, supporting heavy duty loads.

This LIFO flow makes pushback pallet racking ideal for fast-moving SKUs where access to the newest stock is key.

90% more storage than standard selective racks

Common Pushback Rack Design Questions

Help us design the perfect pushback rack solution for your facility

- •What is the available area for pushback rack?

- •What are the dimensions of the pallets (W x D x H)?

- •What is the weight of the pallets being stored?

- •What type of pallet is being stored? Standard GMA pallets? A picture of your pallets would be helpful.

- •What is the clear ceiling height, or max lift height of your forklift?

- •What are your aisle requirements?

Frequently Asked Questions

Common questions about Pushback Rack Systems | High-Density Pushback Pallet Racking & Storage Solutions

Ready to Get Started with Pushback Rack Systems | High-Density Pushback Pallet Racking & Storage Solutions?

Contact us today for a free consultation and custom quote