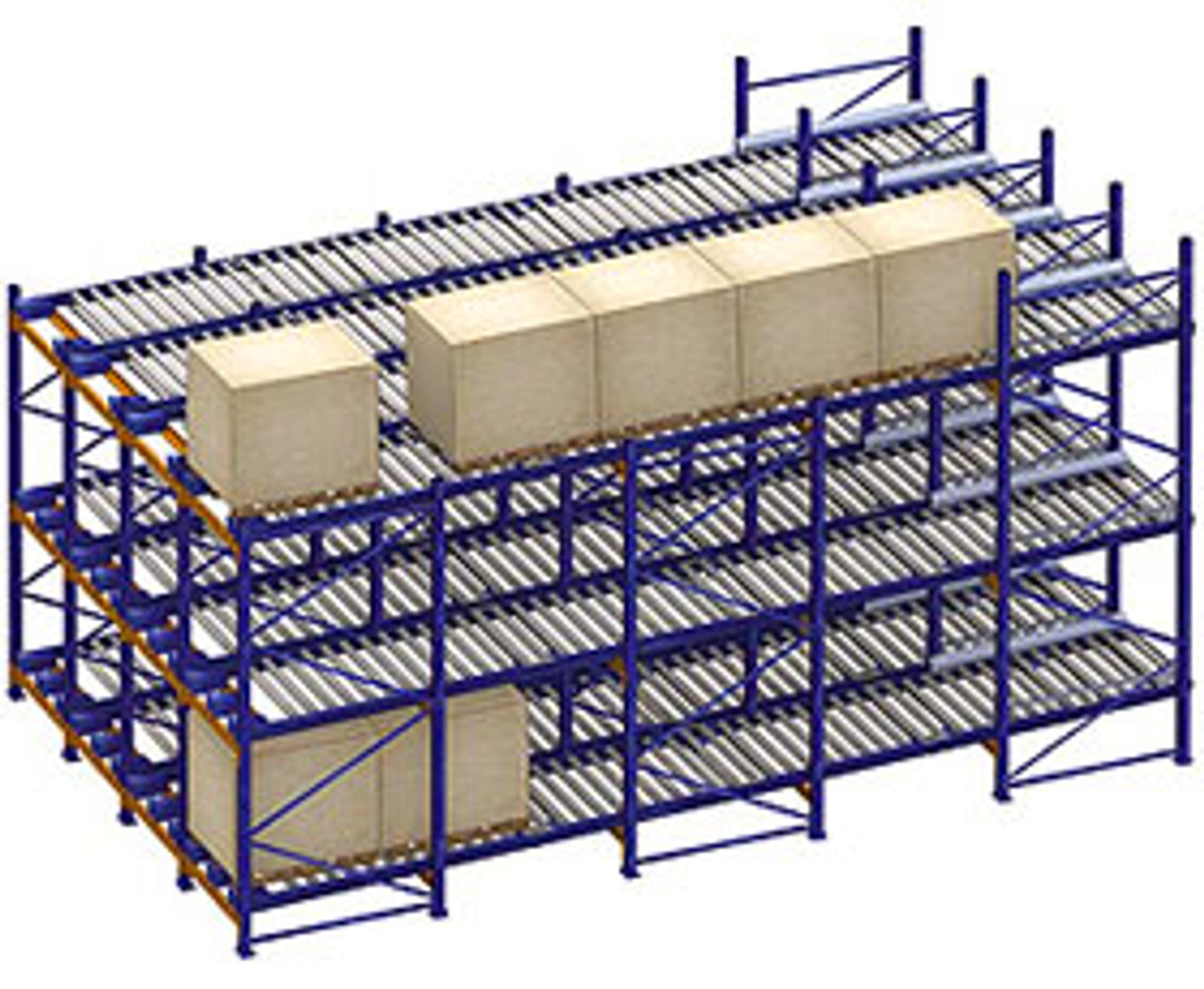

Pallet Flow Rack Systems: Optimize Your Warehouse with Gravity Flow Racking

Elevate your warehouse operations with our innovative pallet flow rack systems, the ultimate solution for high-density storage and seamless inventory management. Whether you're searching for pallet flow rack, pallet flow, or flow racking systems, our gravity-powered designs deliver first-in, first-out (FIFO) efficiency, reducing labor costs and minimizing waste. Built for durability and versatility, these flow through racking and flow racking options handle heavy loads effortlessly, making them perfect for fast-paced environments like distribution centers, cold storage, and manufacturing facilities. Transform your space—explore our customizable pallet flow rack system today.

How Pallet Flow Rack Systems Work

Our pallet flow rack and flow racking systems leverage gravity to create a dynamic, automated storage solution. Here's a step-by-step breakdown:

- Loading Pallets: Forklifts place pallets at the elevated rear entrance of sloped channels equipped with heavy-duty rollers (typically at a 4% incline). Brake rollers control speed to prevent collisions.

- Gravity Flow: Once loaded, pallets slide forward autonomously along the roller tracks toward the front exit. Each channel can hold multiple pallets (up to 30 deep), with the newest entering at the back.

- Unloading: Operators retrieve the oldest pallet from the front in a separate unloading aisle, triggering the next one to flow forward automatically. This FIFO design ensures no stock gets buried.

- Customization: Adjustable lanes accommodate various pallet sizes, and features like pallet centralizers and wire mesh guards enhance safety and precision.

This pallet flow process eliminates manual repositioning, separates loading/unloading traffic, and integrates easily with standard forklifts for uninterrupted workflow.

Common Pallet Flow Rack Design Questions

Help us design the perfect pallet flow rack solution for your facility

- •What is the available area for pallet flow rack?

- •What are the dimensions of the pallets (W x D x H)?

- •What is the weight of the pallets being stored?

- •What type of pallet is being stored? Standard GMA pallets? A picture of your pallets would be helpful.

- •What is the clear ceiling height, or max lift height of your forklift?

- •What are your aisle requirements?

Frequently Asked Questions

Common questions about Pallet Flow Rack

Ready to Get Started with Pallet Flow Rack?

Contact us today for a free consultation and custom quote